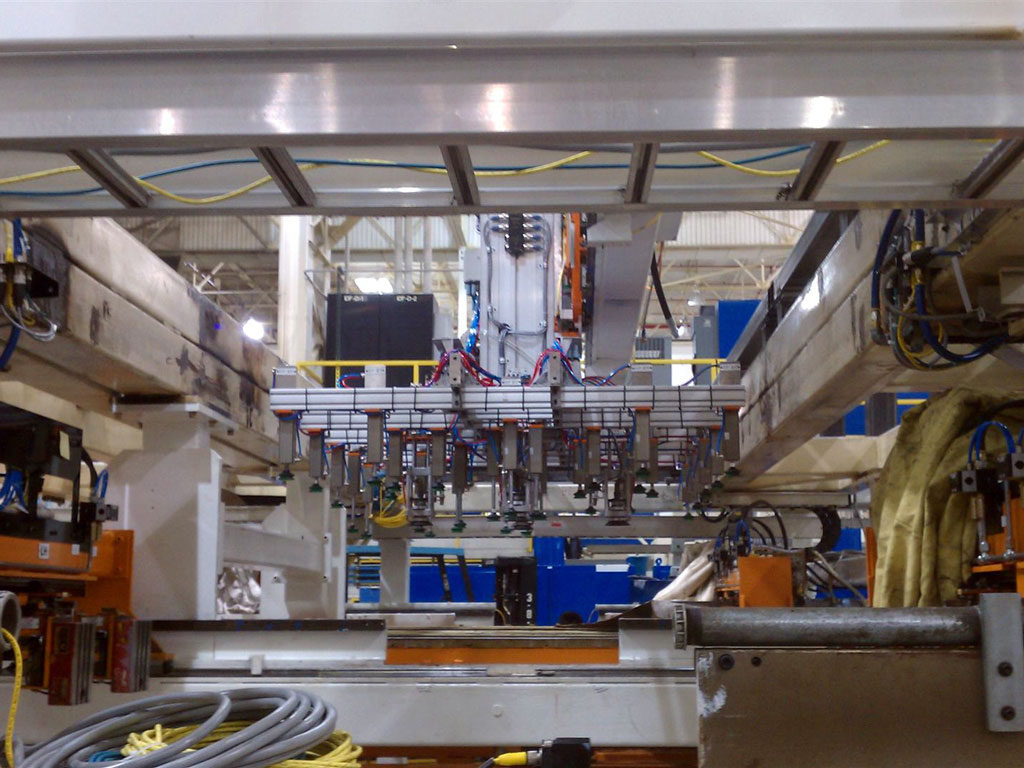

We offer a complete line of Blank Feeding Equipment that is capable of handling your entire blank size and shape requirements.

Items that can impact a Destacker configuration are:

- Press Usage and Material Flow requirements

- Available footprint to utilize for this equipment

- Types of Material to be run (Ferrous / Non Ferrous / Laser Welded / Sheared Blanks / Developed Blanks / Unattached Doubles)

- Cycle Time Requirements

- Continuous Run vs. Non Continuous Run

- Changeover Requirements – Staffing Used and Time Allotted / Manual Change Vs. Automated Change

Destackers are customized to the particular needs of your application.

Call with your part feeding requirements and we will engineer the best solution for you.